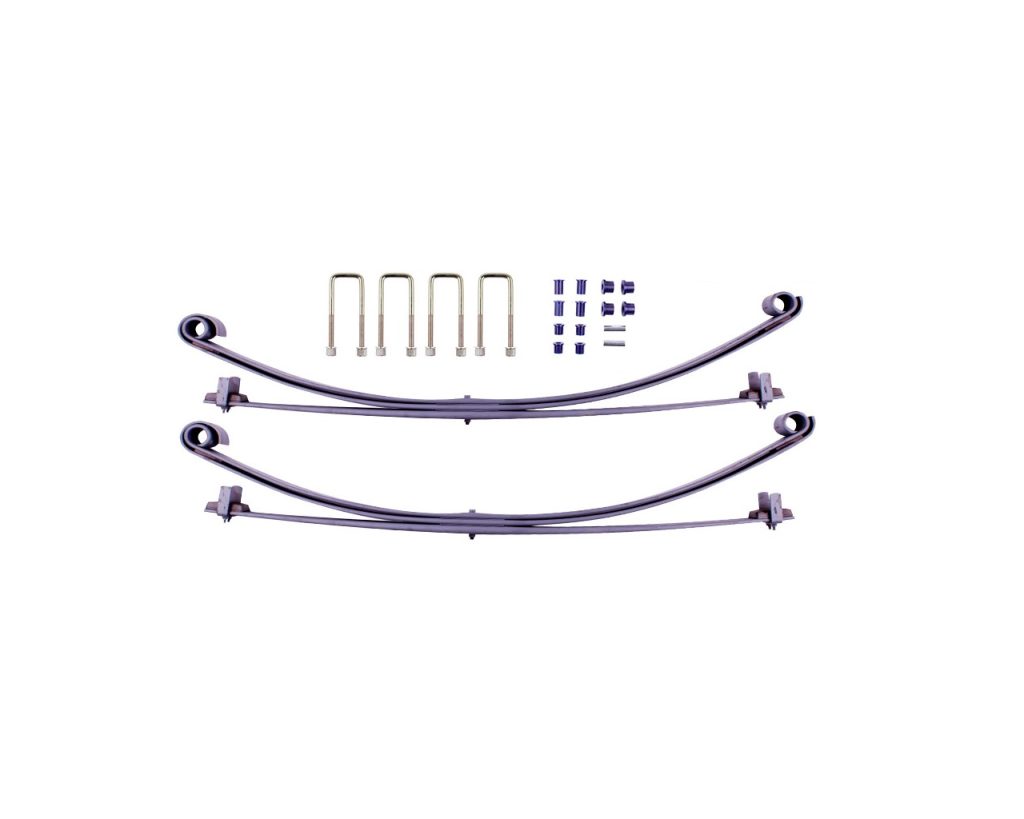

FIREFLEX PARABOLIC LEAF SUSPENSION

The Fireflex Parabolic Spring is a direct replacement for O.E, designed to replace the standard spring without modifications.

Fireflex Parabolic Springs have increased spring rates and capacities to provide greater control whilst maintaining a high level of comfort.

Specifications

Quality Steels –

51CrMoV4 – High Carbon Alloy Spring Steel – Chromium, Vanadium, Molybdenum and Manganese.

50CrV4 – High Carbon Alloy Spring Steel -Chromium, Vanadium and Manganese

Spring material thickness – It can range from 16mm to 60mm in the centre and taper down to approx 12mm to 18mm on the ends

NQ SPRINGS PARABOLIC SPRINGS

Parabolic springs have leaves with a tapered profile. Each parabolic leaf has the same shape & function of a complete multi-leaf spring – thick at the center and thinner at the outer ends. This means that a single parabolic leaf is able to cope with the same forces inside the leaf as a complete conventional multi-leaf or more spring.

The ideal parabolic spring only requires one single leaf but for safety reasons Australian designed 4WD parabolic springs have a minimum of two leaves. The second leaf is a wrap style leaf acting as a safeguard in the unlikely event of a breakage. 100% compatible with standard suspension fittings.

Specifications

- Greatly improved ride comfort over multi-leaf equivalent

- Inter-leaf poly blocks

- Silencer pad on overload leaf

- Shot peened to prevent sagging

- Greatly reduces unsprung weight

- 3 year / 100, 000km warranty

FIREFLEX MULTI-LEAFSPRING

The Fireflex Multi-Leaf Springs are designed as a quality OEM replacement for a vast range of applications.

Fireflex Parabolic Multi Leaf Replacement Springs; This leaf spring change is sometimes required for the purpose of increased vehicle stability, control and load applications

Design and Applications; All springs are designed in accordance with SAE SH778 (1982)

Quality Steels; Grade SUP9 and SUP9A, SAE 5160 and SAE 9258.

Specifications

These proven processes compliment the material used in all Fireflex Leaf Springs. The heat treating and post heat treating (shot peening and presetting) stress relieving methods allow the finished product to achieve increased stress ranges that amplify the service life of your vehicles leave spring suspension

NQ SPRINGS MULTI-LEAFSPRING

The Fireflex Multi-Leaf Springs are designed as a quality OEM replacement for a vast range of applications.

Fireflex Parabolic Multi Leaf Replacement Springs; This leaf spring change is sometimes required for the purpose of increased vehicle stability, control and load applications

Design and Applications; All springs are designed in accordance with SAE SH778 (1982)

Quality Steels; Grade SUP9 and SUP9A, SAE 5160 and SAE 9258.

Specifications

These proven processes compliment the material used in all Fireflex Leaf Springs. The heat treating and post heat treating (shot peening and presetting) stress relieving methods allow the finished product to achieve increased stress ranges that amplify the service life of your vehicles leave spring suspension

FIREFLEX SHOCKS

In 2002 the Fireflex Research and Development Team began the Fireflex Shock Absorber project due to the industry demands for a range of quality truck shock absorbers to suit the specific needs of the Australian Transport Industry.

Specifications

The Fireflex Shock Absorber is designed and developed here in Australia, at the shock absorber Dynamometer Facility in Brisbane. This is where the individual truck and trailer suspension types, vehicle mass, required travel strokes, mount types, ride control and vehicle safety is assess and tested.

Australia’s poor road conditions and extreme heat create build-up in shock absorbers, causing inefficient damping and loss of control. That is why Fireflex is designed with a special high temperature fluid and multi-lip Viton rod seals. Also in addition to this, the piston, bore size, rod and tubing wall thickness are all increased in size for a better damping effect which extends the working life of the shock absorber.

“Build Better to Last Longer”